Good even cone is good conditon and very useful n good injectos

Offset pattern bit alright but it okay to use for a long term it could be nt mch voltage going thorugh the injectors

Poor atomissation is might be some faults on or the fuel pump not operating well.

Dribble my view i think the injector need to be replace no use and it wasting alot of fuel

the specifcation of maufacuter is injector leakage no drops per miniutes

the injecoter flow rates is 177cc per a minute

The fuel injectors numer one was good even cone same as the number 2 and 3. the number 4 was a poor atomistation. i think that has beeen damaged or it need to be clean up so it can be used again.

Testing Ignition Coils

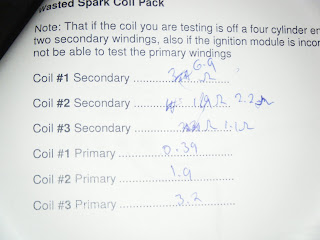

this picture when i was testing two coils the muitmeter and set to 200ohms

the coil 1 when i was testin it was good and it can be seriveable bt the other coil number 2 cant be sevicable there some fualtys in the coils could be a crack or somthing

Now im testin the secondary windings

Testing Ballast Resistors

i have wire up the ballast in the big circuit board and has the ballast on itt

Current draw 4.35v

Coil calcualted voltage drop 40.2v

Coil Measured Voltage drop 0.3v

Ballast resistor calcauted voltage drop 0.09v

Ballast resistor measured voltage drop 12.19v

i caulated the currernt draw and i got 4.35 ohms becasue dat the full ciruits with the ballast and the coil.

Wiring Ignition Systems

i wired the igniton module using a function generator to the trigger. using the colil and spark plug in the circuit to seee if they are firing or nt

atfer i done all the wiring it started to spark and it working then i turned the trigger bit higher and ths spark go faster and faster and making too mch noise for me though because it affected my hearing aids.

Wiring up and igniton module using a distrivutor to the trigger to the module

this project i have done it was working well and it was two start plug firing and it shows the current n the voltages goi through the cicuirt to the start plug to ground.

Wiring up the coil over ingiton system using the funection generator to trigger the module.

it simlar as the first part i did but added 3 startplugs and has coil in it n trigger and also the Amp. Well 3 start plug was firing pefect!

The caultions ccurrent primary 2.5 ohms+ 2.2 ohms.

Tranistor max current is 3mA

12/3 =4ohms

Connect the cirucut up to the function genertator and the start plug

I choosen the wrong resistor 22 ohms it mean to be 2.2ohms and it was to find the datasheet online beacuase i havnt that before ,

Next time i will follower the data sheet correclty and find the right ones to used.

The Throttle Position Angle

The Throttle Position Angle